Experts in automation, robotics, and maintenance

We help our customers streamline processes, reduce downtime, and ensure production reliability.

Automation

We design and implement automation solutions that improve production efficiency, quality, and safety. Our automation systems modernize processes, stabilize production, and provide user-friendly, reliable control for equipment. Our services cover control systems, integrations, programming, and deployments – always tailored to the customer's processes and goals.

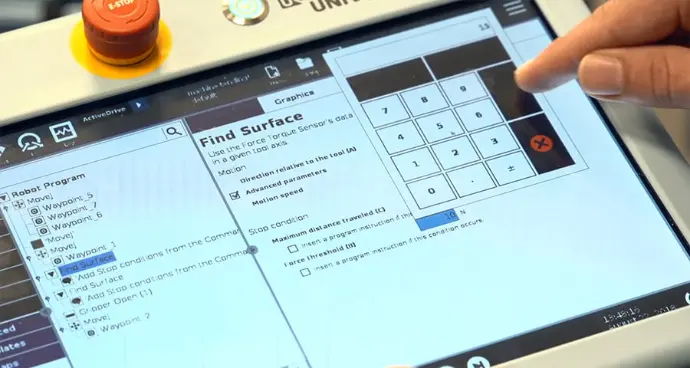

Robotics

We build robotic cells and automated work processes that reduce manual workload and increase production throughput. Our expertise includes UR/ABB/Fanuc robots, welding automation solutions, workpiece handling, assembly, and integration into existing lines.

We implement complete solutions using a turnkey model, from planning to deployment and training.

Machine and equipment solutions

We deliver customized machines and production equipment designed to meet the actual needs of the customer. We build production lines, special machines, lifts, tables, jig solutions, and other production auxiliary equipment that enhance usability and ensure reliable operation. The overall package includes mechanical design, manufacturing, installation, and CE documentation.

Maintenance and lifecycle services

We take care of the performance of the equipment throughout its entire lifespan. Predictive maintenance, scheduled inspections, repairs, and upgrades ensure that production remains reliable and safe. Our goal is to minimize downtime, extend the lifespan of the equipment, and make our customers' lives easier with clear and predictable service.

3D-Scanning

We offer precise and fast 3D scanning with the Artec Leo system, which enables accurate digital modeling of both large and small objects without fixed point cloud devices or markers. The scanning is particularly suitable for modeling spare parts, documentation, installation planning, reverse engineering tasks, and quality assurance. As a result, you will receive an accurate 3D model that can be used in design, manufacturing, and analytics.

Visual Component simulointi

Mallinnamme ja simuloimme tuotantosi työvaiheet, solut ja kokonaiset linjat Visual Components ‑ohjelmistolla ennen varsinaista toteutusta. Simulointi auttaa optimoimaan layoutin, kapasiteetin, robotin liikeradat ja materiaalivirrat jo suunnitteluvaiheessa, mikä vähentää riskejä, lyhentää käyttöönottoa ja parantaa investoinnin kannattavuutta. Toimitamme tarvittaessa myös visuaaliset esitykset ja analyysit päätöksenteon tueksi.

Asennus ja kunnossapito mittaukset

We perform precise installation measurements of production machines and structures to ensure correct height positions, straightness, and alignments before commissioning. Our measurement services identify deviations in a timely manner, reduce installation errors, and shorten downtimes. We ensure that machines, switches, and structures are positioned exactly in their planned locations — safely and durably.

Are you ready to solve your production challenges?

Contact us today, and we can help you develop processes, streamline workflows, and reduce downtime.

Your solutions for more efficient production start here.