Robotics

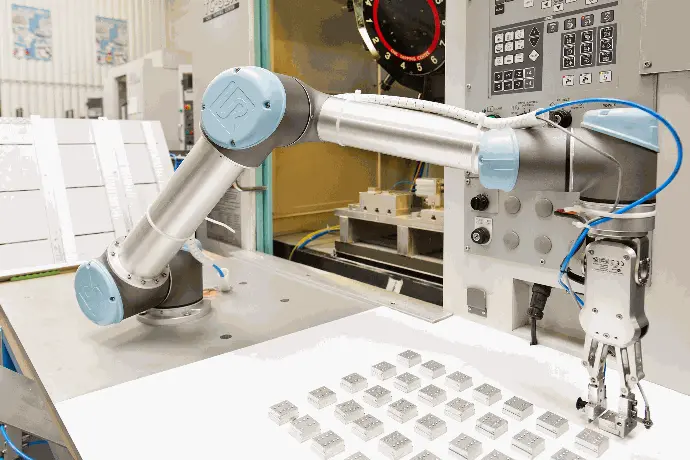

We use collaboration robots from the Universal Robots brand and we do projects in collaboration with Machine Tool Ltd. The goal of robotics is to make people's work more efficient, and collaborative robots are also known as cobots and can assist people in many different tasks.

Cobots can work side by side and perform a wide variety of tasks, such as workpiece handling, screwing, welding, grinding, handling pallets and operating a turning center.

They enable employees to be freed from burdensome and repetitive tasks, which increases work productivity and significantly reduces human errors in production.

With automation, the investment in robotics quickly pays for itself. A cobot working alongside a human brings practicality, flexibility and cost efficiency to work.

Universal Robots' collaborative robots can also be re-placed/taught for new tasks easily, which means that the purpose of use is versatile.

CNC / machinery robots

The collaborative robot makes machine service part handling more efficient, such as measurement, assembly, welding and part feeding. The robot improves the utilization rate of machines, such as CNC milling machines or injection molding machines, as well as production efficiency and quality.

We are able to streamline production processes in terms of handling tasks and utilize robotics in quality control with the help of a plug and play camera. The collaborative robot picks defective or out-of-spec parts out of the process

With the collaboration robot, you can perform fast and demanding assembly, such as handling, placing, assembling and screwing parts.

Many production steps can be automated, and materials can be removed and finished by polishing and grinding - the built-in force detection also works on curved and uneven surfaces.

Food industry

Robotics in the food industry brings significant benefits to the production process.

Ergonomics are improved with cobots, because people are not required to perform heavy and repetitive work steps, such as lifting and moving packages. With the collaboration robot, a person can work next to and with the robot, but omits repetitive heavy steps.

Various robotics processes increase productivity and enable higher volume production.

In addition, robots can improve the quality and consistency of products and reduce waste.

With mechanized work, bakeries can better respond to growing demand and gain a competitive advantage in the market.

Packaging and staging

Pallet robotics offers efficient and precise solutions for loading pallets in industry and logistics. Reduce logistics costs and make it easier to pack and ship a diverse range of products.

Automation improves productivity and reduces costs. State-of-the-art technology ensures optimal pallet filling and the formation of stable stacking solutions.

Watch the video: Collaborative robots, track processing and packaging at work.

Additional devices and peripherals

Universal Robots' unique UR+ ecosystem offers hundreds of ready-made accessories and software.

A wide selection of ready-made tools enables the robot's work task to be changed easily and reduces the risk of the investment, because the robot can be repositioned for another work task or it can be used for several tasks.

We work in cooperation with Machine Tool.

Join us and let's make production more efficient together.

Suunnittelemme

Suunnittelemme kaiken valmiiksi, olipa kyseessä huolto, uusi laite tai uudistaminen.

Toteutamme

Teemme valmiiksi avaimet käteen metodilla, mutta asiakas on kaikessa mukana ja tietää mitä tapahtuu; milloin, miksi ja miten.

Maintenance

Huollamme ja pidämme kunnossa tuotannon kaikki koneet ja laitteet.